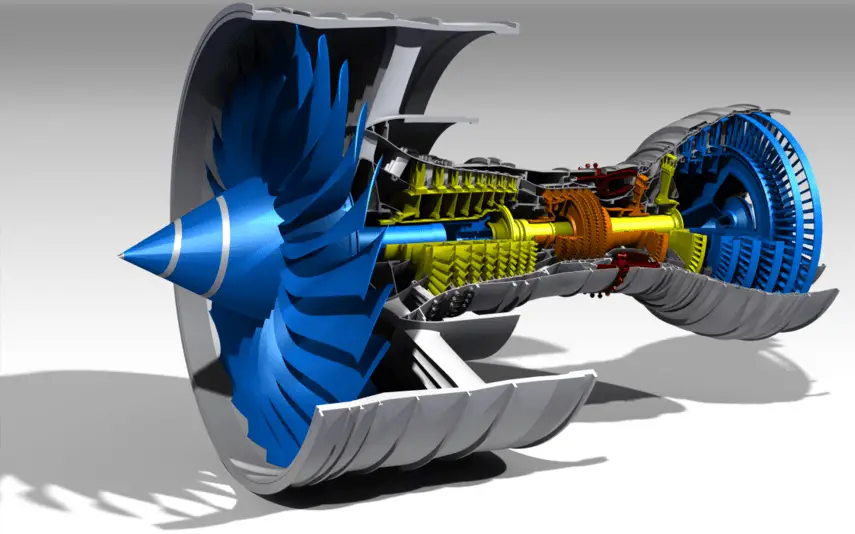

CAM machines can be programmed to create the same product repeatedly with unmatched precision. This makes CAM highly consistent and reliable. All this without compromising on accuracy. Advantages of Computer-Aided Manufacturing Fast and accurateĬomputer-aided manufacturing can significantly speed up the manufacturing process. Let’s look at some of the advantages that CAM systems provided to manufacturers.

It had several other features that added immense value to a manufacturing setup. The modifications in a manufacturing process were easier and faster to perform. CAM ushered in the era of flexible automation as opposed to the traditional fixed automation systems. It transfigured the manufacturing industry in many ways. The introduction of CAM was a turning point in the manufacturing industry. With this process, CAM can manufacture virtually any shape by depositing layer upon layer of compatible materials until the desired shape is ready. 3D printingĬAM can also control additive manufacturing processes such as 3D printing effectively. They can perform a variety of carpentry operations on various materials such as wood, composites, steel, glass and plastic via CNC. CNC routersĬNC routers use similar working logic to milling machines, removing excess material from a workpiece. With CAM, we can control these sparks to cut the workpiece with a high degree of precision. These sparks reach extremely high temperatures enabling them to cut through any material quite easily. Electrical discharge machinesĮlectrical discharge machines create parts by propagating an electric spark through them. Plasma cutting is useful for conductive materials such as metals. They can also engrave workpieces as and when needed. Waterjet, laser and plasma cuttingĬNC can automate the different types of cutting machines to carve workpieces with phenomenal accuracy. These machines are also capable of other processes such as carving threads, knurling, chamfering, facing, etc.

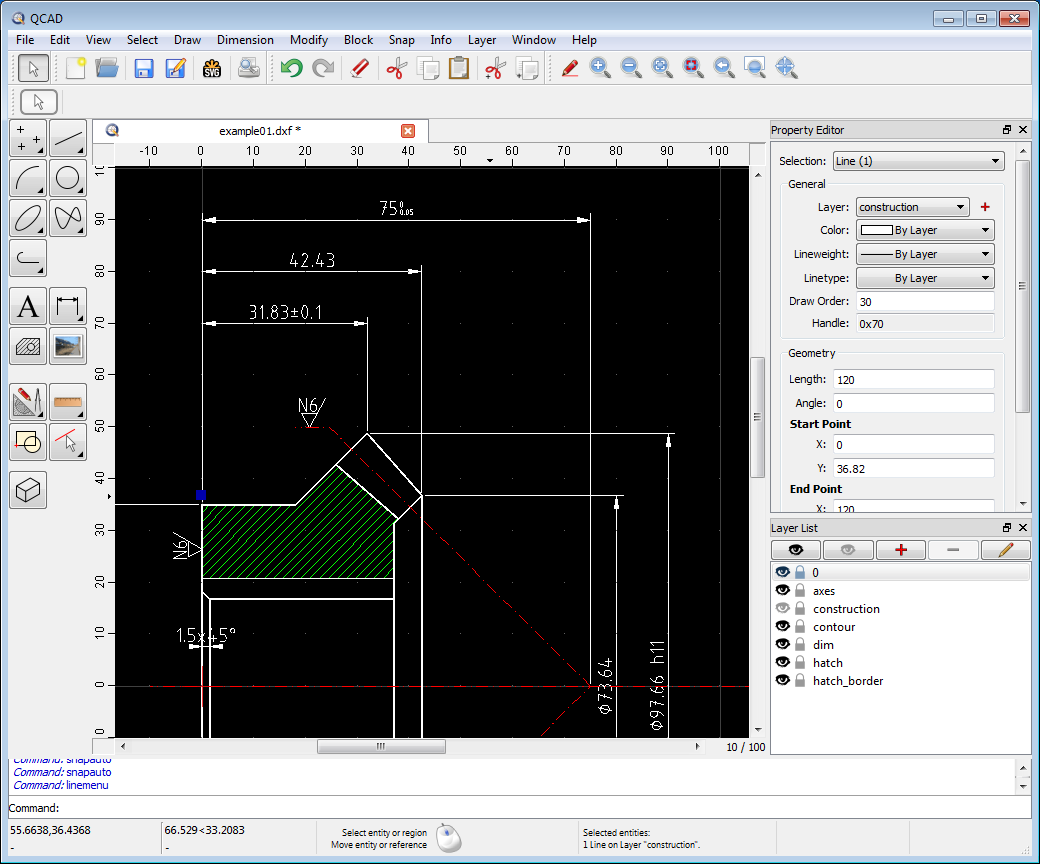

CNC lathe machines are very efficient when creating the right order of procedure for creating the final product. The turning process removes excess material from a workpiece by rotating it against the machine tool. The use of CAM with CNC machining enables using the data for quick quotes on machining jobs. Through CAM, the machinists can accurately remove excess material from workpiece blocks.

MillingĬAM can automate the milling of workpieces in applications where there is a need for subtractive manufacturing. CAM can automate the following processes. These machines follow their supplied G codes and M codes to machine a workpiece. These processes are carried out by means of CNC machines (Computer Numerical Control). We can control a variety of processes with CAM systems. VI Popular CAD/CAM tools Manufacturing Processes Automated by CAM

0 kommentar(er)

0 kommentar(er)